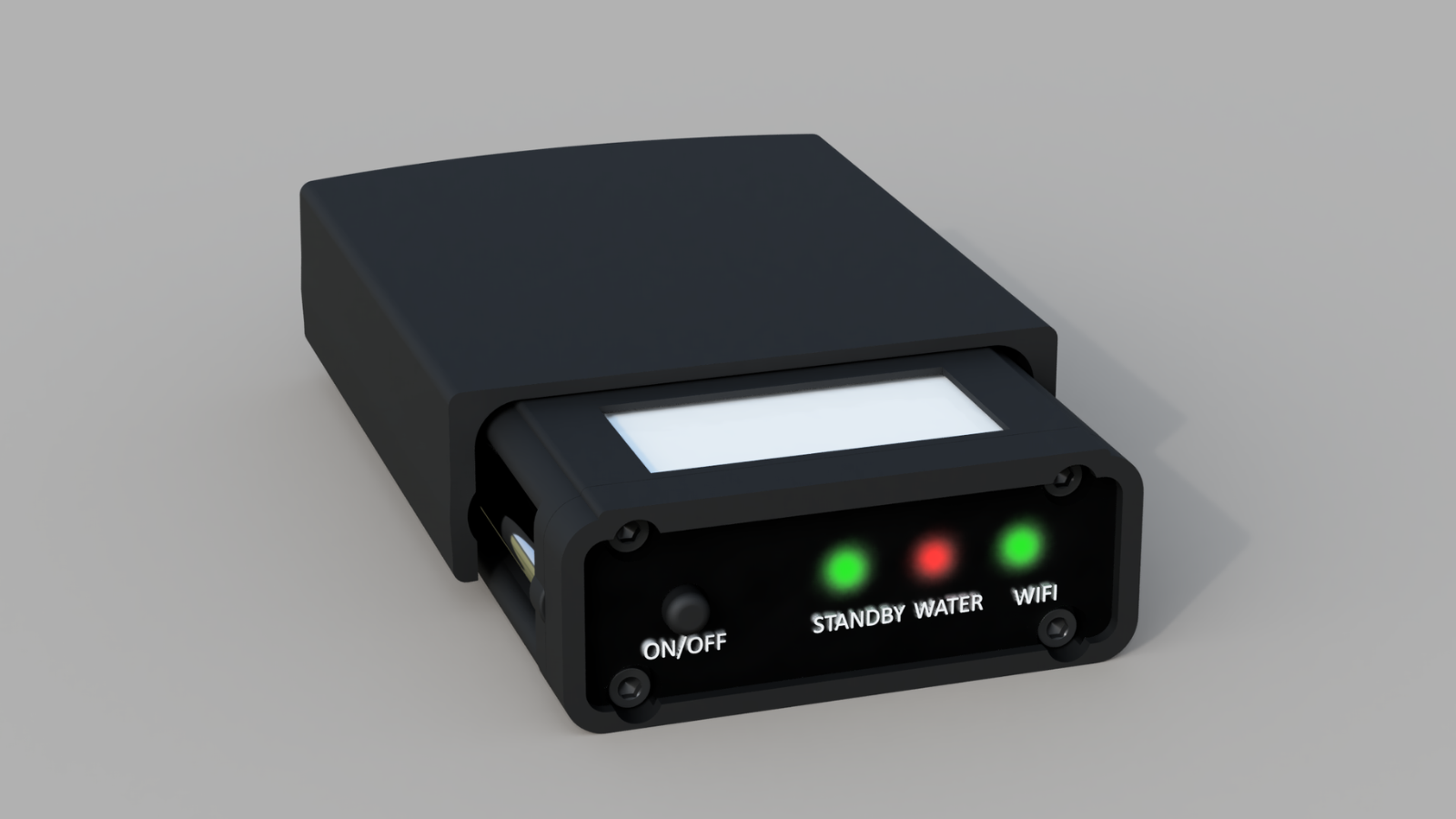

Material:

ABS, HIPS, PETG, PLA, ASA, PA12

Model finish:

Depending on the printing settings, satin or glossy, small marks from the use of 3D printing technology.

Features of prints:

Depends on the material used and the print setting.

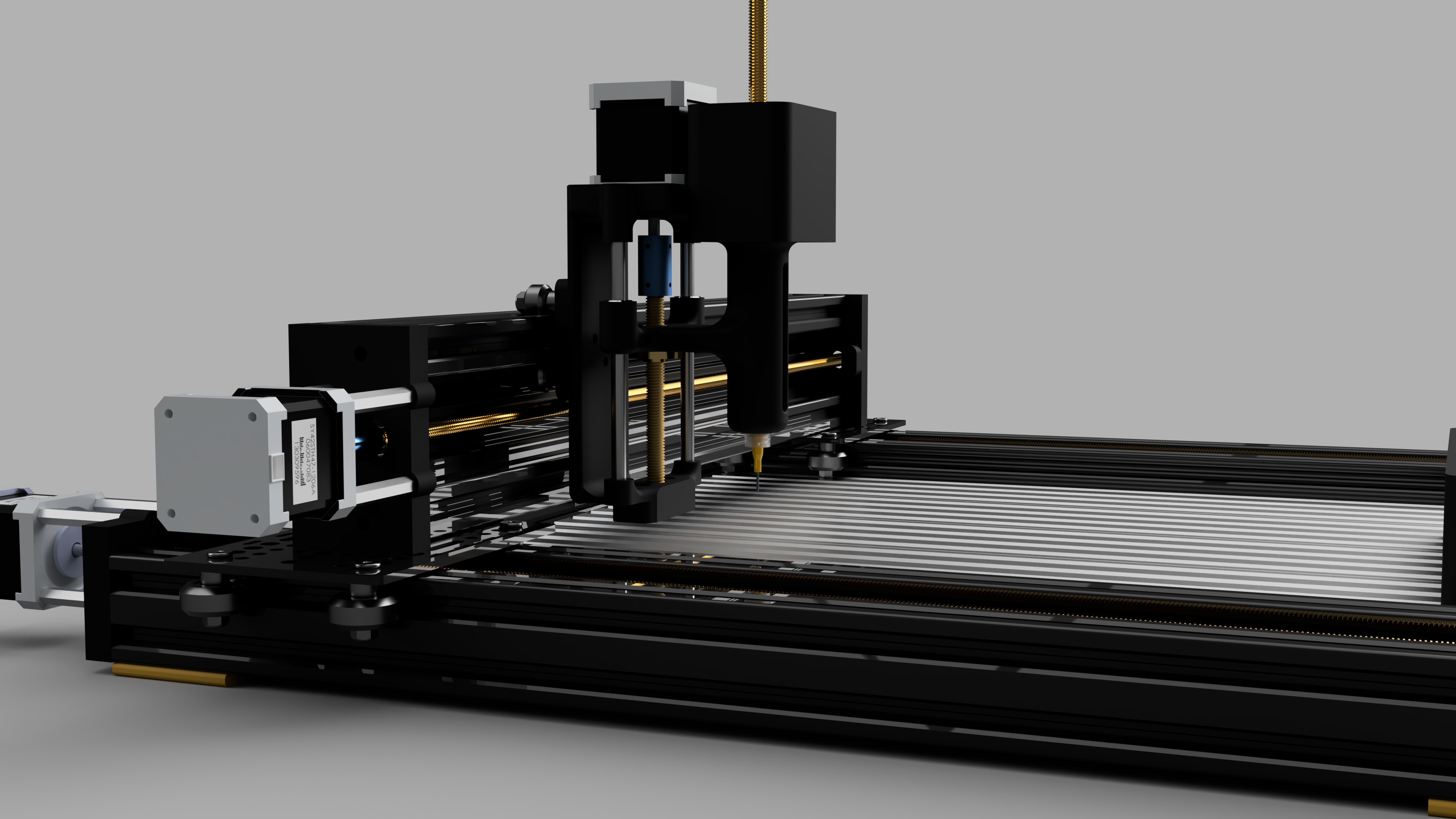

Application:

Budget production and prototype series, fixtures and mechanical components